We offers a comprehensive range of Supplies And Services for Motors, Drives, Controls, Generators And UPS Systems. The quality systems of operation conform to Indian standards. State Of The Art Manufacturing, designing And marketing abilities. |

| |

Shunt Wound Motor |

"Electric motors are machines that change electrical energy into mechanical energy in order to do work. It's all about one magnet pulling (attracting) and pushing (repelling) another magnet." |

| |

|

| |

| Motor Characteristics: |

| Direct-Current Motors |

DC motors are divided into three classes, designated according to the method of connecting the armature and the field windings as shunt-series and compound wound. |

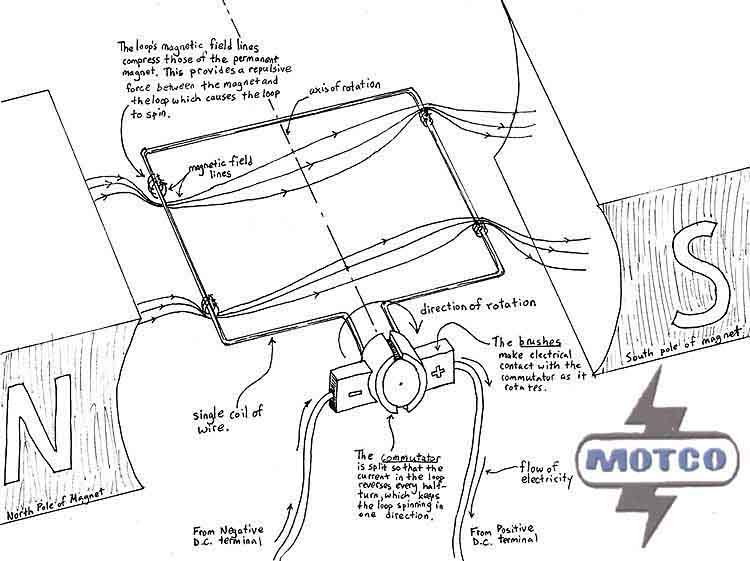

There are different kinds of D.C. motors, but they all work on the same principles. To understand what goes on inside a motor, here is an example (click the illustration below for a full size image). |

|

|

Simple Motor

When a permanent magnet is positioned around a loop of wire that is hooked up to a D.C. power source, we have the basics of a D.C. motor. In order to make the loop of wire spin, we have to connect a battery or DC power supply between its ends, and support it so it can spin about its axis. To allow the rotor to turn without twisting the wires, the ends of the wire loop are connected to a set of contacts called the commutator, which rubs against a set of conductors called the brushes. The brushes make electrical contact with the commutator as it spins, and are connected to the positive and negative leads of the power source, allowing electricity to flow through the loop. The electricity flowing through the loop creates a magnetic field that interacts with the magnetic field of the permanent magnet to make the loop spin. |

| |

| |

| Shunt Wound Motors |

This type of motor runs practically constant speed, regardless of the load. It is the type generally used in commercial practice and is usually recommended where starting conditions are not usually severs. Speed of the shunt-wound motors may be regulated in two ways: first, by inserting resistance in series with the armature, thus decreasing speed: and second, by inserting resistance in the field circuit, the speed will vary with each change in load: in the latter, the speeds is practically constant for any setting of the controller. This latter is the most generally used for adjustable-speed service, as in the case of machine tools.

The shunt motor is probably the most common dc motor used in industry today. Components of the shunt motor are the armature, labeled A1 and A2, and the field, labeled F1 and F2. The coils in the shunt field are composed of many turns of small wire, resulting in low shunt field current and moderate armature current. This motor provides starting torque that varies with the load applied and good speed regulation by controlling the shunt field voltage. If the shunt motor loses it’s field it will accelerate slightly until CEMF rises to a value sufficient to shut off the torque producing current. In other words, the shunt motor will not destroy itself if it loses its field, but it won’t have the torque required to do the job it was designed for.

Some of the common uses of the shunt motor are machine shop lathes, and industry process lines where speed and tension control are critical. |

| |

| |

| Series-Wound DC Motors |

This type of motor speed varies automatically with the load, increasing as the load decreases. Use of series motor is generally limited to case where a heavy power demand is necessary to bring the machine up to speed, as in the case of certain elevator and hoist installations, for steelcars, etc. Series-wound motors should never be used where the motor cab be started without load, since they will race to a dangerous degree.

Components of a series motor include the armature, labeled A1 and A2, and the field, S1 and S2. The same current is impressed upon the armature and the series field. The coils in the series field are made of a few turns of large gauge wire, to facilitate large current flow. This provides high starting torque, approximately 2 ¼ times the rated load torque. Series motor armatures are usually lap wound. Lap windings are good for high current, low voltage applications because they have additional parallel paths for current flow. Series motors have very poor speed control, running slowly with heavy loads and quickly with light loads. A series motor should never drive machines with a belt. If the belt breaks, the load would be removed and cause the motor to over speed and destroy itself in a matter of seconds.

Common uses of the series motor include crane hoists, where large heavy loads will be raised and lowered and bridge and trolley drives on large overhead cranes. The series motor provides the starting torque required for moving large loads. Traction motors used to drive trains are series motors that provide the required torque and horsepower to get massive amounts of weight moving |

| |

|

| Compound-Wound DC Motors |

A combination of the shunt wound and series wound types combines the characteristics of both. Characteristics may be varied by varying the combination of the two windings. These motors are generally used where severe starting conditions are met and constant speed is required at the same time

When comparing the advantages of the series and shunt motors, the series motor has greater torque capabilities while the shunt motor has more constant and controllable speed over various loads. These two desirable characteristics can be found in the same motor by placing both a series field and shunt field winding on the same pole. Thus, we have the compound motor.

The compound motor responds better to heavy load changes than a shunt motor because of the increased current through the series field coils. This boosts the field strength, providing added torque and speeds.

If a shunt coil is added to a series motor at light loads (when a series motor tends to over speed) the added shunt field flux limits the top speed, eliminating self-destruction.

Common uses of the compound motor include elevators, air compressors, conveyors, presses and shears. Compound motors can be operated as shunt motors by disconnecting the series field. Many manufacturing process lines are designed this way. The reason being that, most off the shelf motors are compound motors, and the series field can always be connected later to provide additional torque, if needed.

Compound motors can be connected two ways, cumulatively and differentially. When connected cumulatively, the series field is connected to aid the shunt field, providing faster response than a straight shunt motor. When connected differentially, the series field opposes the shunt field. Differentially connected compound motors are sometimes referred to as “suicide motors,” because of their penchant for self destruction. If perhaps, the shunt field circuit were to suddenly open during loading, the series field would then assume control and the polarity of all fields would reverse. This results in the motor stopping, and then restarting in the opposite direction. It then operates as an unloaded series motor and will destroy itself. Differentially connected motors can also start in the opposite direction if the load is too heavy. Therefore, it is seldom used in industry |

| Back to the top |

|

| Squirrel-Cage Induction Motors |

The most simple and reliable of all electric motors. Essentially a constant speed machine, which is adaptable for users under all but the most severe starting conditions. Requires little attention as there are no commutator or slip rings, yet operates with good efficiency.

Wound-Rotor (Slip Ring) Induction motor - Used for constant speed-service requiring a heavier starting torque than is obtainable with squirrel cage type. Because of its lower starting current, this type is frequently used instead of the squirrel-cage type in larger sizes. These motors are also used for varying-speed-service. Speed varies with this load, so that they should not be used where constant speed at each adjustment is required, as for machine tools.

Single Phase Induction Motors - This motor is used mostly in small sizes, where polyphase current is not available. Characteristics are not as good as the polyphase motor and for size larger that 10 HP, the line disturbance is likely to be objectionable. These motors are commonly used for light starting and for running loads up to 1/3 HP Capacitor and repulsion types provide greater torque and are built in sizes up to 10 HP.

Synchronous Motors - Run at constant speed fixed by frequency of the system. Require direct current for excitation and have low starting torque. For large motor-generators sets, frequency changes, air compressors and similar apparatus which permits starting under a light load, for which they are generally used. These motors are used with considerable advantage, particularly on large power systems, because of their inherent ability to improve the power factor of the system. |

| |

| << BACK |